Inspection of Wire Rope

Inspection of Wire Rope

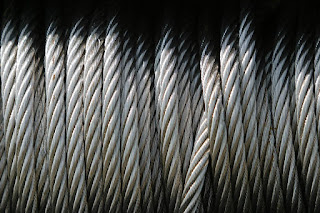

Wire Rope is a construction of a bunch of several individual

wires twisted together (known as Strands) in a particular Lay direction depending

on its applications.

Application of Wire Rope

Wire ropes are most widely used for Lifting material/equipment with the support of Cranes or other suitable equipment. Now it is most widely used for industrial applications across the industry and as a Lift in Office / Mall / Business center

– where people travel from one floor to another floor.

Points to be checked in Wire Rope

Considering the Wire rope application and severity proper Inspection of

wire rope prior to its use is very much important.

The following points are to be taken into consideration with the inspection of

Wire Ropes

-

Dimensions – The Dimensions are the Number of Strands,

Number of wires in strands, Length, Dia of Strand /Wire Ropes, Lay Direction,

-

Constructions – Prior to the Construction of the wire

Rope the following factors are to be considered depending on the use and application of the Wire Rope

Strength

Abrasion resistance

Flexibility

Resistance to cursing

Fatigue or Endurance Strength

Corrosion resistance

-

Grade of Raw material used for Wire Rope

Construction-

-

Lubrication

-

Finish

Third-Party Inspection agencies are performing Third-Party Inspection of Wire Rope . Also as per Industry Exper view and recommendation, Third-Party Inspection is most recommended by Experts to overall improve the supply-Chain, reduce the Inspection Cost, Reduce the overhead cost of In-house Inspection, and Improve product supply and Delivery on time. and finally, Experts say that Reduced Rejections and improves the reliability of products . It is most recommended to the majority of Buyers and Industry Experts for Third- Party Inspections from accredited Third-Party Inspection agencies.

Comments

Post a Comment